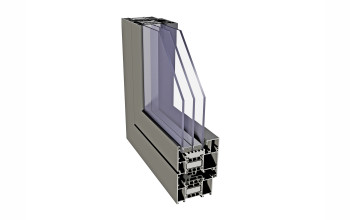

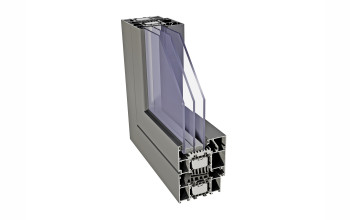

The use of modern and durable insulating glass units made of the highest quality components has a positive effect on the heat transfer coefficient of the entire window and, consequently, on the energy balance of the entire house. Appropriate selection of panes from the many available types improves the comfort of use and safety. Insulating glass units can include any glass configurations, gaining properties that ensure security and protection against attack, thermal insulation, protection against the sun, protection against noise and decorative values.

Aluminum window and door profiles are painted with powder paints. The availability of a rich range of colors makes it possible to obtain an elegant and harmonious appearance of the building, depending on the inventiveness of the designers. Powder paints are characterized by good mechanical parameters, resistance to chemicals, light, changing weather conditions while maintaining the degree of gloss and color stability.

Proper assembly of windows and doors ensures their proper functioning, but also tightness by minimizing thermal bridges. The method of installation must be adapted to the structure of the wall and the materials it is made of. During assembly works, we use a warm polystyrene window sill as a standard, the task of which is to seal the places most exposed to heat loss. At the customer’s request, we can also install a warm window sill made of XPS extruded polystyrene.

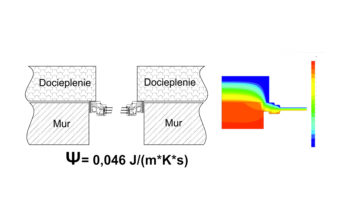

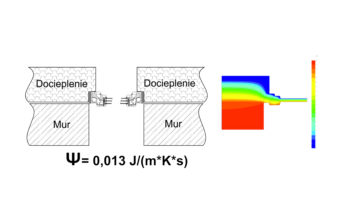

Taking into account the value of the thermal conductivity coefficient (Ѱ), the customer can choose the appropriate type of assembly:

- assembly in the wall, the window is extended approx. 1 cm outside the wall (Ѱ = 0.046 J/(m*K*S)

- installation in the insulation zone (so-called warm installation), window protruding directly behind the wall (Ѱ = 0.013 J/(m*K*S)

A feature of the installation that reduces the impact of moisture is the use of three layers of materials in the contact area between the window and the wall. The inner layer made of a vapor barrier foil protects the mounting foam against the penetration of moisture from the inside of the building. The middle layer made of polyurethane foam permanently eliminates thermal bridges. The outer layer is made of a vapour-permeable tape that insulates the connections between the wall and the window frame and protects against the penetration of moisture inside, while allowing it to be led outside the building.

Another option is to use only self-adhesive polyurethane expansion tape that meets the requirements of energy-saving assembly. It provides vapor tightness from the inside, thermal and acoustic insulation of the middle layer and resistance to UV and weather conditions from the outside. Its use does not require special preparation of the substrate, it does not emit volatile substances.

We also offer our customers installation in the building insulation layer, the task of which is to eliminate thermal bridges around the frame. In this case, the window is placed in front of the wall, but it is attached to the wall using anchors, consoles or special installation frames. In addition, foam is used as thermal insulation and vapor-permeable and vapor-tight tapes.

Installation in the insulation zone